A cricket ball has a cork core with tightly wrapped string layers and a leather casing with a slightly elevated sewed seam. The covering of a high-quality ball suitable for the high-level competition is made up of four pieces of leather formed like the peel of a quartered orange, but one hemisphere is rotated 90 degrees from the other. The 'equator' of the ball is sewn with thread in six rows to make the ball's noticeable seam. The quarter seam is formed by stitching the last two joints between the leather pieces inside.

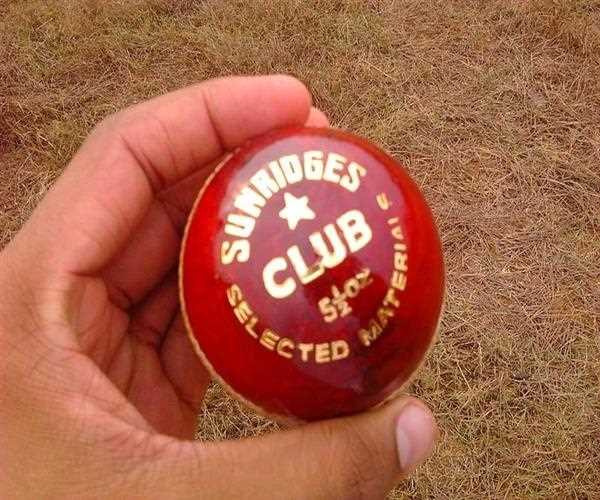

Lower-quality balls with a two-piece covering are also popular for practice and lower-level competition due to their lower cost.

The nature of the cricket ball differs depending on the manufacturer. In one-day and Twenty20 international matches, white Kookaburra balls are used, whereas red Kookaburra balls are used in test matches in the majority of the twelve test-playing nations, with the exception of the West Indies, Ireland, and England, who use Dukes, and India, who use SG balls.

A cricket ball is a solid, hard ball used in the sport of cricket. A cricket ball is made out of a cork core coiled with thread and a leather cover stitched on, and its construction is governed by first-class cricket law. The action of the bowler, as well as the condition of the ball and the pitch, influence the trajectory of a cricket ball as it is delivered, through movement in the air and off the ground, while working on the cricket ball to achieve optimal condition is a major responsibility of the fielding side. The batsman scores run mostly by hitting the ball with the bat into a position where it would be safe to take a run or by directing the ball through or beyond the boundary.